Processing and manufacturing precision moulds, parts of precision moulds, etc.

Source of information:internet Published on:2021-05-14

The materials used for punching of Dongguan metal stamping parts should have sufficient plasticity and low hardness to improve the quality of the punching section and dimensional accuracy. Among them, soft materials (such as brass) have good punching performance, hard materials (such as stainless steel, high-carbon steel) have poor punching section quality, and brittle materials are prone to tearing during punching.

Precision metal processing has been widely used at present. We can use precision metal processing to produce the items we need every day. Although we know precision metal processing, many friends still don’t know what processes are involved in precision metal processing. share.

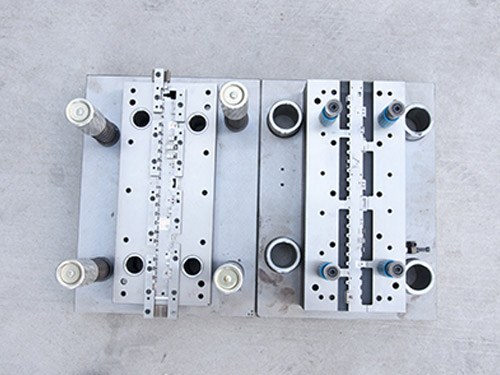

The manufacture of metal molds generally involves several processes such as forging, cutting, and heat treatment. Several major technological properties of hardware molds:

The service life of metal stamping molds is related to many factors such as mold structure design, mold steel selection, heat treatment, surface treatment, machining and grinding, wire cutting technology, stamping equipment, stamping materials and technology, mold lubrication, poor maintenance and repair

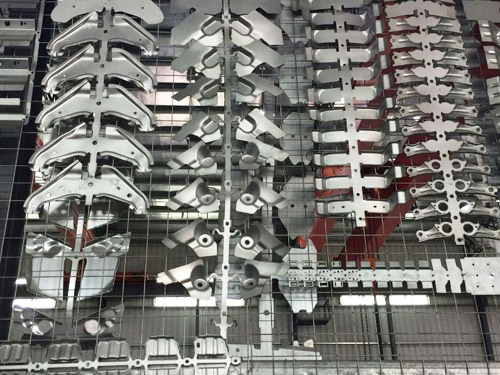

In the processing of precision parts, metal stamping processing occupies a large part. Let's understand what the process performance of precision metal stamping processing is: Casting performance refers to some process performances of whether a metal or alloy is suitable for casting, mainly including flow performance, the ability to fill the mold; shrinkage, the ability to shrink the volume when the casting is solidified; segregation refers to Inhomogeneity of chemical composition.

About us

- Company profile - Plant equipment - Honor - PartnerProducts

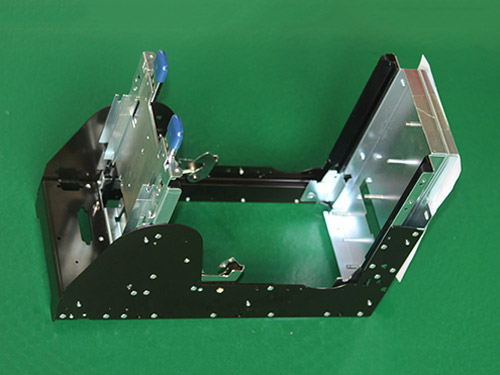

- Non standard parts and accessories - Precision stamping die parts - Precision plastic mold parts - Precision automation equipment partsNews center

- News information - Technical support - Common problem

Scan, mobile browsing

Scan, mobile browsing

Dongguan Youdi Precision Mold Products Co., Ltd. © Copyright technical support: Netone Technology 【GMAP】 【BMAP】 【Website management】 【GO TOP】